How It Helps

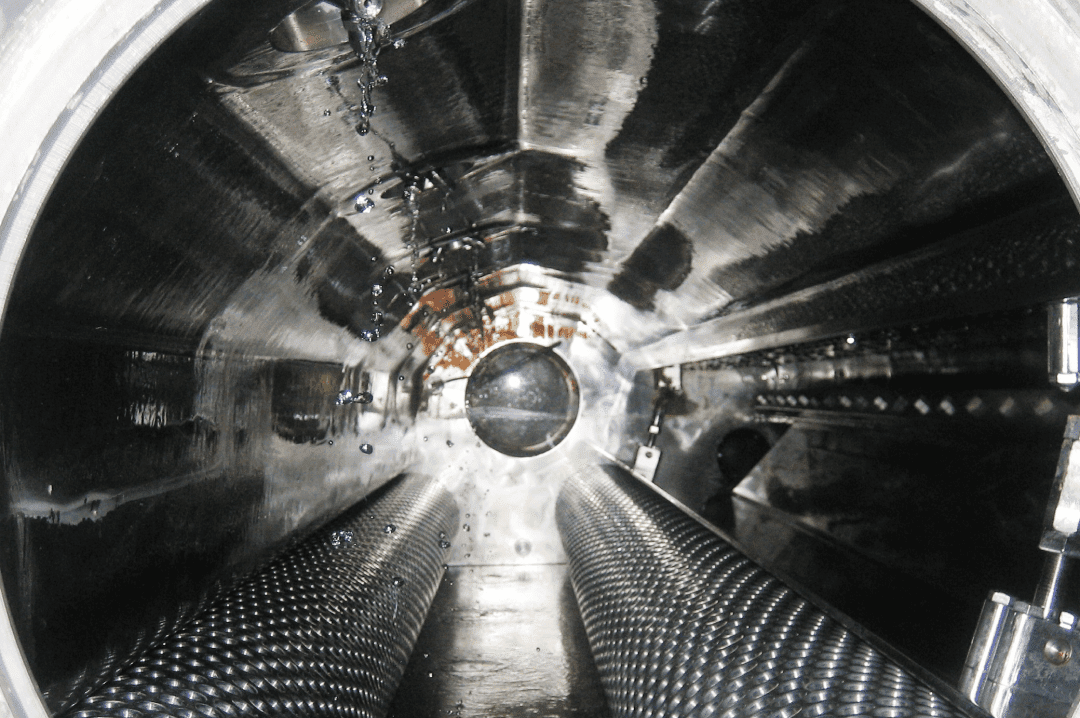

Deposition in pulp and paper mill systems can destroy a mill's profitability as off-spec pulp or paper is produced and costly unscheduled shutdowns are taken. A planned chemical cleaning program can reduce these deposit-related problems and assist the mill in achieving its papermaking goals while positively contributing to its bottom line. Typical applications would include various market sectors such as pulping process applications, printing & writing, newsprint & deinking, packaging & board and tissue & towels.

Application Areas

Using boilout chemicals provides various benefits such as improved runnability, reduced levels of rejects / off-grade papers, reduced startup problems, reduced downtime required for cleaning, and ensures consistent results. Boilout chemicals are typically applied in the following areas of the paper machine:

- Approach loop

- Long loop

- Size press

- Coater

- Additive systems

Products

Amazon Papyrus has a range of cleaning chemicals to provide papermakers with the most appropriate cleaning program and monitoring that ensure safe, effective and consistent applications.

Our cleaning products are specially formulated to address various deposits/scales commonly found in pulp & paper making systems. On-site monitoring ensures the program's safe application and cost-effective treatments. Our experts will work with you to select the most appropriate products to meet your needs.

AmiClean AP product range comprises a broad range of cleaning agents which can be used effectively to remove unwanted deposition on machine surfaces. It combines the benefits of alkali / acid sources, surfactants, chelants, sequestrants, solvents, self-released oxidizing agents, enzymes, and wetting agents.

Ask Our Experts