How It Helps

Strength aids are employed for dry strength, wet strength and wet-web strength. Different polymers are selected for compressive strengths such as concora, ring crush and ECT and extensive strengths such as burst, tensile and fold. Dry strength aids provide the following benefits:

- Increased paper strength.

- Increased filler levels.

- Increased stiffness.

- Increased bulk and drainage.

- Inclusion of weaker fibres.

- Reduced stock refining.

Wet strength aids are used to increase the strength of re-wetted paper. A paper is described as wet strengthened when it retains a minimum of 15% of its dry strength upon re-wetting. Wet strength agents find application in paper grades such as label paper, poster, sack, bag kraft and wallpaper; in tissue grades such as facial, towelling and napkins; and in the board grades such as liquid packaging board, freezer board and carrier board. Speciality papers such as currency, tea bags and coffee filters would also require wet strength. Special grade wet strength resins are available to meet the stringent regulations for direct food contact. Wet web strength aids are special agents employed during the paper making process to strengthen the wet paper web before the drying section, to improve machine runnability and productivity.

Application Areas

Dry strength aids are typically added by stock addition, spraying or size press application. Wet strength aids are typically added to the thick stock of the paper machine system. Wet web strength aids are usually added into the thin stock of the paper machine system.

Products

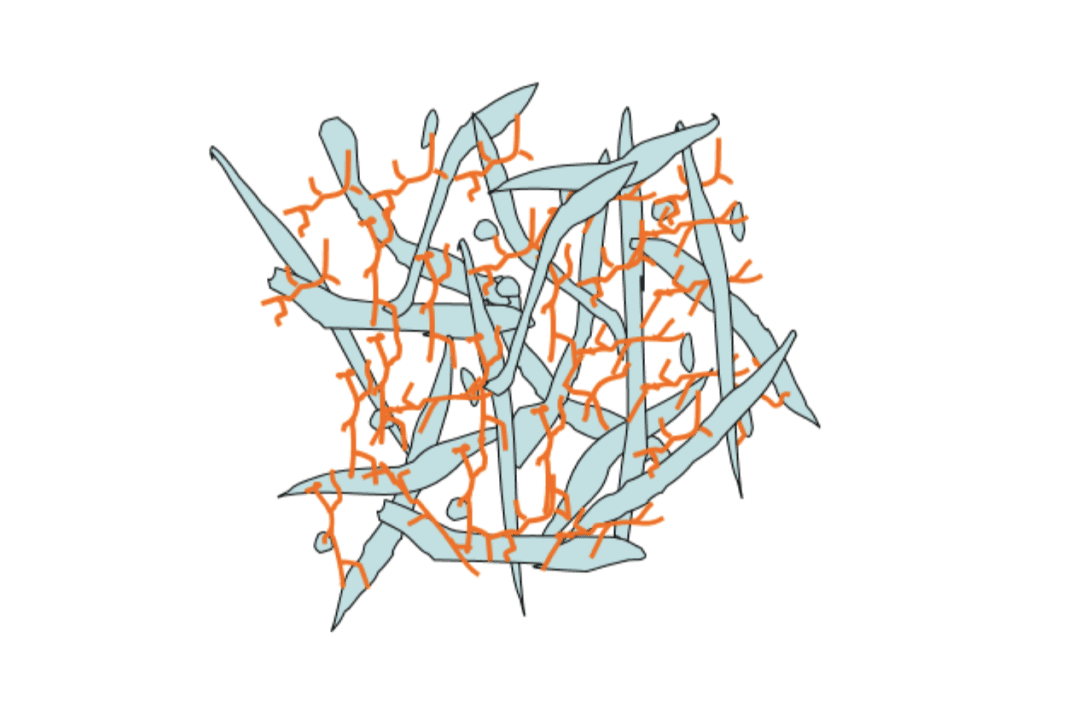

AmiBond DS comprises several product chemistries that increase bonding within paper and board. These products may be anionic, cationic or amphoteric, based on natural “green” materials or synthetic polymers and of linear, branched or sub-branched molecular configurations. Certain products may be selected to meet the isoelectric point of the system or for an appropriate charge density to match the system conductivity. Different products are recommended depending on the type of strength required, e.g. extensive strength such as burst or compressive strength such as ring crush.

AmiBond WS comprises a range of wet strength resins for the paper and board which require wet strength properties, such as sack, bag kraft, packaging board, posters, wallpaper, label paper, kitchen towels, facial tissue, tea bags, coffee filters and other food contact papers. The WS series includes 1st generation products, 2nd generation products to comply with FDA standards and 3rd generation products to meet low DCP & CPD specifications in the finished products. We also have products to give temporary wet strength, i.e. the wet strength slowly diminishes after re-wetting, facilitating re-pulping or disposal of the paper.

Amazon Papyrus has a range of strength aids for use in low- and high-charged systems that employ bleached, unbleached, virgin or waste-based furnishes. Our professionals will work with you to select the most appropriate products to meet your needs.

Ask Our Experts