How It Helps

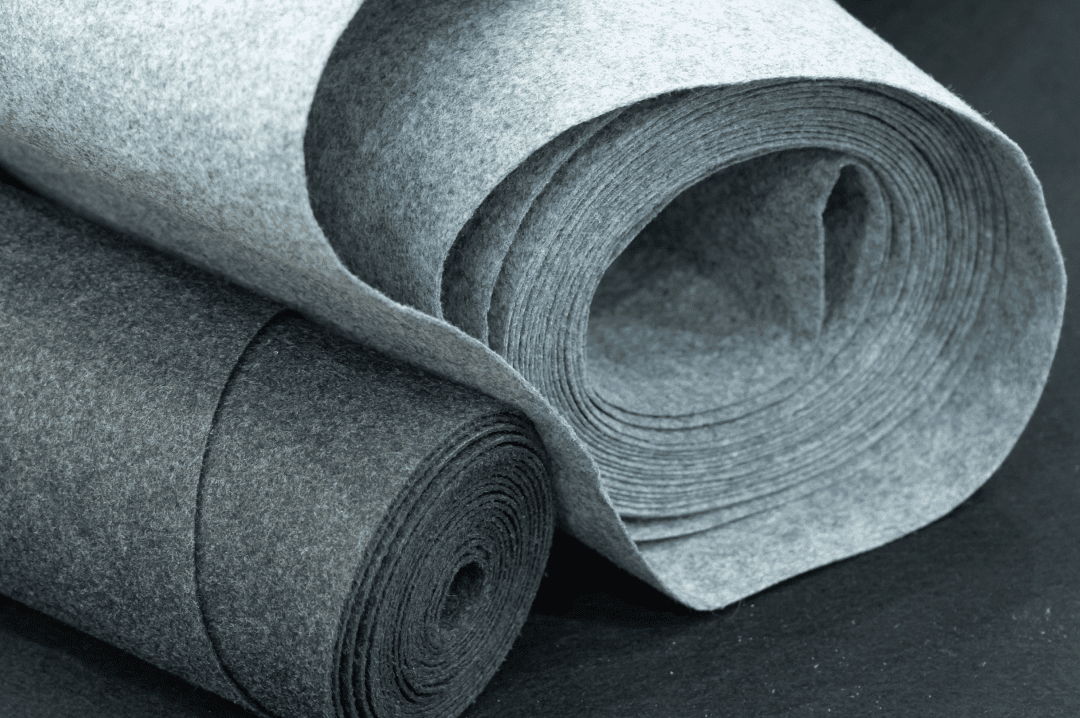

Felt cleaners and conditioners enable pulp dryers and paper machines to run continuously without the need to stop for cleaning the press felts, thus significantly enhancing productivity. The selection of cleaners and conditioners would depend on the type of contaminant in the felt, and the use of a proper conditioner slows down the rate of your felts becoming dirty.

The use of felt cleaners and conditioners facilitates good maintenance of the press felts and would provide the following benefits:

- Maximization of press dewatering

- Reduced press section breaks

- Reduced sheet moisture streaks

- Improved evenness of size press and coater pickup (on the paper machine)

- Improved evenness of pulp sheet (no curling) on pulp dryers

- Increased machine speed or reduce steam use in the dryer section

Application Areas

Press felt cleaners and conditioners are typically applied through the felt showers.

Different grades of paper, machine types/sizes and other operating conditions have different requirements, ranging from traditional batch cleaners to Batch-On-The-Run to continuous conditioning. Different applications would also call for different feed points and concentrations.

Some applications may require dedicated chemical showers in the press section, while others make use of existing lubrication or cleaning showers.

Products

Amazon Papyrus has a range of felt cleaners and conditioners including blends of dispersants / surfactants / alkali / chelants / solvents and heavy-duty solvent-free cleaners that are FDA and BGVV-approved. Our products can even clean your felts while you continue to make on-specification paper.

Our team of professionals would work with you to select the most appropriate products to meet your specific needs. With the correct program in place, shutting down your large capacity pulp dryers and paper machines to clean the felts would be a thing of the past.

Ask Our Experts