How It Helps

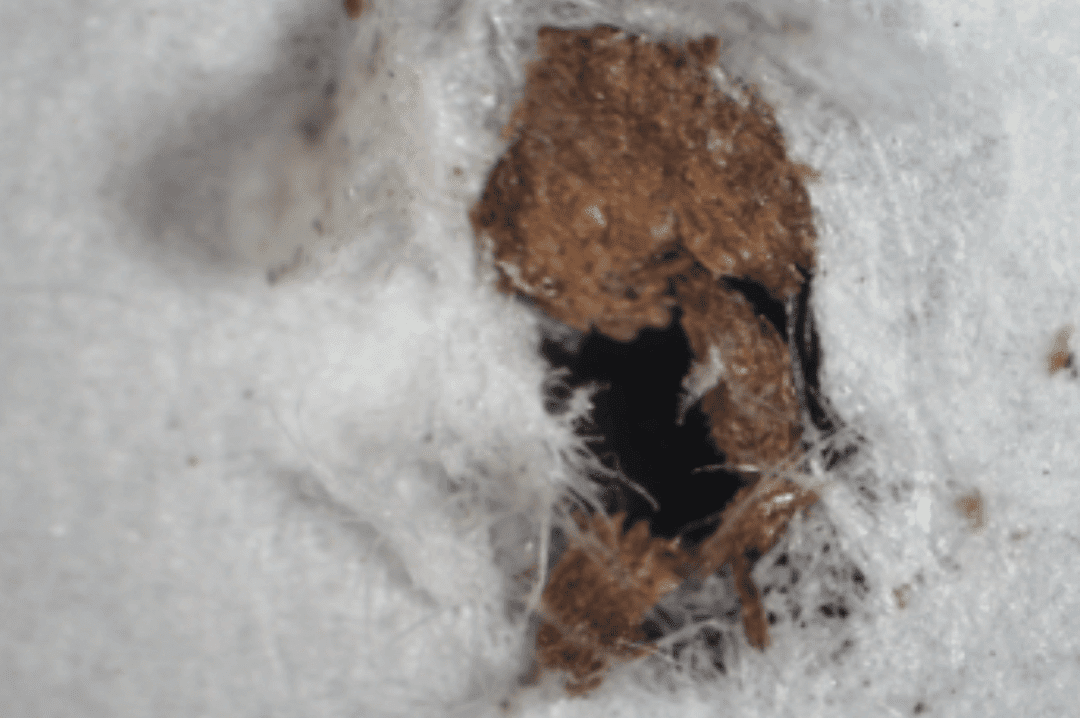

Pitch deposits (on their own or agglomerated with other inorganics) can appear anywhere in the Pulp & Paper making process. It could occur in places ranging from the pulp washing plant, screening, bleaching, stock preparation, wet end of pulp dryer or a paper machine to the final product, i.e. pulp or paper. The wood's resin interferes with other additives and causes sheet defects ( Dirt of blue deposits), breaks, etc. The shortage of fibrous raw materials, mixing of two different raw materials and limitations on debarking increase the need for pitch control. A combination of different chemistries (Surfactant, Dispersants encapsulations etc) provides the following benefits:

- Effective removal of Resin/Pitch from fibre in the early stages of production.

- Control of pitch deposition in the entire fibre line.

- Minimization of dirt and Extractive content in pulp and paper sheets.

Using alternative raw materials like Acacia and younger wood increases the overall resin content in the pulp (DCM Extractive in most paper-grade pulp range from 0.15 to 0.35%). The solvent used for extracting the resins defines its name as DCM extractive or Benzene Acetone Extractive. Surfactant and dispersant based chemistries are used in the pulp mill process (Digester, Washing, ODL and bleaching) to reduce the overall resin content in the pulp.

Application Areas

Various products like Digester additives and Pitch/Resin control agents are typically used at multiple feed points in the pulp mill process: digesters, brown stock washing process, oxygen delignification, bleaching process and pulp dryers. Encapsulation-based chemistries are typically used in pulp dryers and less complex open systems (Less degree of recirculation).

Localized treatments, such as wire passivation and felt conditioning, can be cost-effective alternatives for pitch problems in pulp dryers and paper machines.

Products

Amazon Papyrus has a wide range of products to address specific targets. Our primary chemistries range from non-ionic surfactants/dispersants, anionic dispersants, and encapsulation chemistry to remove the pitch from the pulp and wash out in the process.

AmiSperse and AmiPac products perform in a wide range of environment 50-170 oC and 3-12 pH, including applications in the presence of chlorine dioxide and Hydrogen Peroxide. Our professionals will work with you to select the most appropriate products to meet your needs.

Ask Our Experts