How It Helps

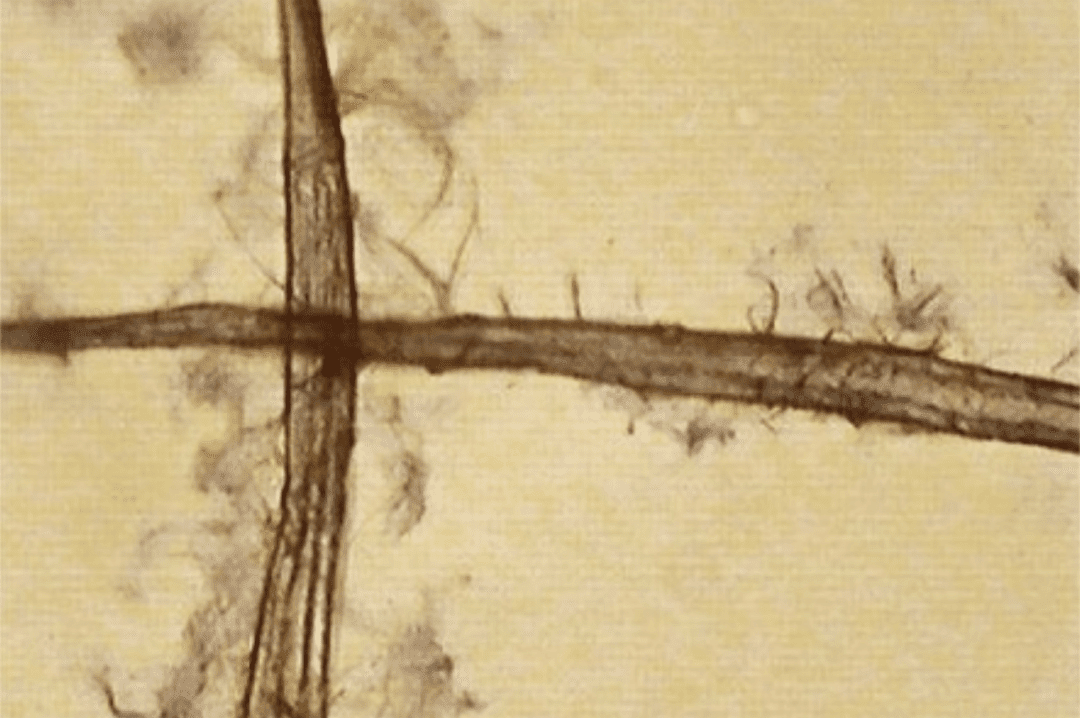

Stricter regulatory requirements and increasing demand for greener technology have increased demand for specific and environment-friendly technologies. Enzymes play a significant role in providing effective solutions. Careful selection of the appropriate type of enzyme is crucial as enzymes are used for specific objectives and in different areas of the papermaking process. Typical applications include pulping process applications, printing and writing, Newsprint & deinking, packaging and board, and tissue & towels.

Special enzymes help to achieve this:

- In Pulping process, there is a vast range of enzymes and each type of enzyme is used in the pulp mill to achieve particular objectives.

Application Areas

There are different needs, ranging from DCM extractives reduction in pulp to improving bleachability/brightness and lowering of bleaching chemical requirement, reducing refining energy for high yield pulping such as APMP and BCTMP grades.

- In tissue production, harsh treatments are used to break down wet strength resins for better recycling of mill broke. Cost-effective solutions for breaking wet strength resins are being explored commercially.

- In Printing & Writing, Several types of enzymes are used in the printing and writing segment to achieve specific objectives. Typically, these include refining energy reduction, fibre modification, fines management and viscosity modification of starches. Refining energy reduction is an important aspect of paper making in fibres like softwood with high refining demand. Fibre modification, development, vessels and fines management are essential requirements for refining shorter fibres such as hardwood, agro and mechanical pulps. A combination of chemical energy (enzymatic action) and mechanical energy (refining) usually offers the best solution in dealing with such fibres. Viscosity modification of starches facilitated by enzymes is the oldest enzyme application in the paper industry and specific enzymes help achieve these objectives.

- In Newsprint, several types of enzymes are used in the newsprint market segment to achieve specific objectives. Typically, these include fines management, stickies control and deinking. Drainage enzymes effectively clean up the system from colloidal fines, which hamper drainage on the newsprint machines. These enzymes work with polymer-based products to effectively deal with drainage issues. Ongoing intensive research is being conducted to develop enzymatic counterparts of conventional deinking and stickies management.

- In Packaging & Board, Several types of enzymes are used in the packaging and board segment to achieve specific objectives. Typically, these include refining energy reduction, fibre modification, fines management and viscosity modification of starches. Requirements for long fibres such as softwood are managed with cellulase enzymes, which increase the fibrillation to improve strength properties and reduce refining energy. Fibre modification and development are important factors for shorter fibres such as hardwood and mechanical pulp, where costs can be reduced through energy cost saving and improved productivity. Waste paper-based mills have to deal with weaker fibres/excessive fines and enzymes can play a vital role in managing the productivity of the machines in addition to increasing the recycled content. Viscosity modification of starches by enzymes is an important application for size press starches.

Products

Amazon Papyrus has a range of enzymes to meet specific objectives. Our professionals will work with you to select the most appropriate products to meet your needs. Careful selection of the proper type of enzyme is crucial as enzymes are used for specific objectives and in different areas of the papermaking process. The added benefit of green technology not only provides cost-effective and environmentally friendly solutions but also serves as an option in situations where conventional chemicals fail.

Ask Our Experts